manufacture in india : trusted craftmanship

FABRIC EXPANSION JOINTS & BELLOWS

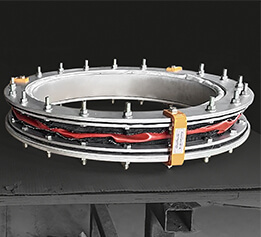

Fabric expansion joints are extremely flexible and can be made from a variety of special woven fabrics coated or laminated with selected elastomers or fluoropolymers. Fabric bellows are used to insulate, to avoid mechanical loads and to protect against abrasion.

The main advantage of a fabric expansion joint for pipework design is that it can absorb movements simultaneously in several directions. Further, fabric bellows have almost no reactive forces and require little space. Fabric bellows are easy to customize to suit existing operating conditions and are easy to transport and install.

In comparison to metallic expansion joints; fabric expansion joints offer almost unlimited flexibility by giving pipework designers more options. Mostly, fabric expansion joints are installed in systems operating with low pressure and dry media.

BELMAN FABRIC EXPANSION JOINTS

Belman Expansion Joints

since 1994

Belman Design Styles

Belt type expansion joint attached directly onto the outside of the duct using clamping bands normally used for:

1. Low temperatures (up to 300°C)

2. Low to medium velocity

3. Low to medium dust load

i.e.: Clean air ducts

Convoluted fabric expansion joints are attached directly onto the outside of the duct using clamping bands normally used for:

1. Large movements

2. Low velocity

3. Low dust content

4. Low temperature

i.e.: Pulp and paper industry

Fabric expansion joints mounted on vertical flanges, typically used in systems with:

1. Low flow velocity

2. Low dust content

3. Low temperature (up to 450°C)

The design can be made both with and without sleeve. The sleeve primarily acts to protect the fabric expansion joint from the particles in the flow medium

i.e.: Chemical industry (wet and dry)

Fabric expansion joints mounted on parallel flanges, typically used in ductwork with:

1. Medium temperature range (up to 500°C)

2. Higher flow velocities

3. Medium dust content in the flow

i.e.: Low temperature flue gas ductwork in conventional power stations

Fabric expansion joints mounted on parallel flanges with insulation bolster, typically used in plants with:

1. High temperatures (up to 600°C)

2. High dust content

3. High flow

i.e.: High temperature flue gas duct systems in

conventional power stations

Fabric expansion joints with floating sleeve construction are typically used in plants with:

1. Medium to high temperatures (up to 600°C)

2. Very high dust content

3. Low to high flow velocities

The floating sleeve gives good protection against

dust whilst allowing lateral movement.

i.e.: Cement industry

Hot to cold duct transition is often made in combination with a fabric expansion joint.

The purpose of the hot to cold duct transition is to be able to use a lower grade (and less expensive) duct material, by incorporating the insulation internally in the duct. Temperatures up to 650°C

i.e.: Gas turbine installations

Fabric expansion joints installed in refractory lined duct systems are typically used in plants with:

1. Very high temperatures (up to 1200°C)

2. Low to high dust content

3. Low to high flow velocity

i.e.: Incineration plants

Customised Designs

In addition to the styles shown here, we assist our clients in India with very special applications such as,

“picture-frame” units, pantographic linkage, pipe penetration seals and other special arrangements including “dog-bone” seals

for low-pressure ductwork carrying condensates and fluids.

Further details are available on request.

Technical Descriptions

data sheets

Experience our Professional engineering Support

CONTACT US

Please feel free to leave us a message and we will contact you as soon as possible.

“It’s easy to contact us”

READY TO BUY ?

Get in touch with a Belman Expansion Joint Specialist that can assist you with,

- One to one expansion joint replacement

- New expansion joint project

- Improvement of an existing expansion joint

- Other expansion joint project requirements

Experience our help center, where we have stored most of FAQS & key questions that we have been asked frequently.

Your question might also be listed with a quick answer.

Take a tour by clicking below ..